Pig slaughter equipment Cow slaughter equipment Sheep slaughter equipment Sheep slaughter process flow diagram Pig slaughter process flow diagram Cattle slaughtered process flow diagram

-

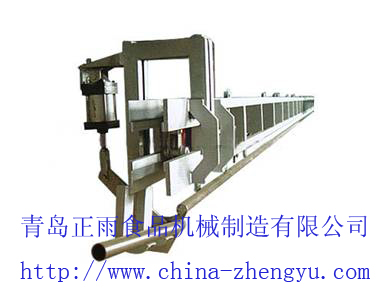

- Step conveyor

The series of slaughtering equipment is introduced foreign advanced equipment, our company developed, automated process for cattle slaughter line conveyor. Slaughter machine is mainly applied to cattle, horses slaughter plant automation assembly-line production line, complete wrangling, chest, take the internal organs, split in half and a series of processes Tel :0532 -8,521,312,813,708,968,090 13977223670 Contact: Manager Liu

- Step conveyorDetail

Step conveyor Details Features: This series of slaughtering equipment is introduced foreign advanced equipment, our company developed, automated process for cattle slaughter line conveyor. The use of automatic control, mechanical drive system with pneumatic drive to work together to meet the needs of different processes. Slaughter equipment for the air suspension of the lifting equipment, mainly by the drive, chassis, tensioner devices, equipment replacement and upgrade Tuitou (beating cylinder) and so on. The machine is mainly applied to slaughter cattle, horse slaughter plant automated assembly-line production line, complete wrangling, chest, take the internal organs, split in half and a series of processes, high degree of automation, low labor intensity, is necessary to slaughter cattle slaughter and processing equipment.

Methods of operation:

1 method of operation of the ride into two: one for the automatic control operation; one for manual control operations. Instructions from the switch, the operating position are laid in the electrical control panel, indicated by the word mark and transfer with delivery device.

(2) automatic control procedures: the machine every two-step distance of 2.4 meters, for an operation, stop operation, grouped three to push, to stretch the claw, the five limit switch control.

3 manual step sequence: Please switch for electrical control cabinet, rotating to the stepper machine manual, cylinder manual position; stepper button to start the run, so the first push to enhance the pulley not far away from the claw (0.1 meters) , stepper button down, buttons to move the cylinder, will provide the first set of cattle by the pulley wheel at this time to run, the second with eight self-stepper beginning of the track. In the third pulley to push the second set of claws not far away (0.1 meters), stepper machine stop, start cylinder, so that the pulley frame hold up to mention cattle, start stepping machine running, push the claw from the third pulley belt into the station, shut down operations. Depending on the station work is completed, according to the above-mentioned step sequence, a re-operation. Note that cattle pulley hanging rail joints must be pulled high and low stops.

4 not fully proficient in the operation of the case, to exercise appropriate manual operation, automatic control operation gradually.

Maintenance:

1 machine operating system more complex, highly responsible, should be equipped with hand operation, the operator should have the mechanical, electrical, pneumatic and other basic qualities.

2 stepper sprocket shaft bearing for the two copper tiles bearing top with oil cup, filling each class not less than twice (machine oil).

3. Cycloid reducer in oil content should be marked in the oil line. Replacement of the initial operation of 300 hours or so once the oil, replace every 6 months after the first oil. Recommended to use 40 # or 50 # engine oil.

4 regular checks of the electrical part of the trip switch and the pneumatic part of the sensitivity and found that timely repair and replacement. The aircraft is equipped with reversing device that made a mistake, or other circumstances occur that can be used to manually reverse button to rewind the object handle and trim.